About Us

PROVIDING ASME CODE & NON CODE INDUSTRIAL FLANGES

Elite Piping is a leading manufacturer specializing in high-quality carbon steel, stainless steel, alloy steel, aluminum alloy, and nickel-based alloy pipes and forgings flanges. We have complete forging, heat-treatment, and machining capabilities and can satisfy customized OEM requirements for Non-standard or Special-purpose flanges and forgings; the annual output capability is around 28,000 tons.

Elite Piping has its own laboratory and various testing and inspection equipment, and it can serve and satisfy various tests according to customers’ requirements. We have obtained ISO9001, ISO14001, OHSAS18001, PED, API 6A, and Q1 certificates, and production and management are strictly by the standards. In the meantime, Elite Piping has got approval from YPF, ICOFC, and EIL; these approvals may greatly improve management and market competition.

Most Popular Flanges

API 6A Stainless Steel Flange

SS400 Carbon Steel Blind Flange

ANSI B16.47 Long Weld Flange

ANSI B16.47 Compact Flange

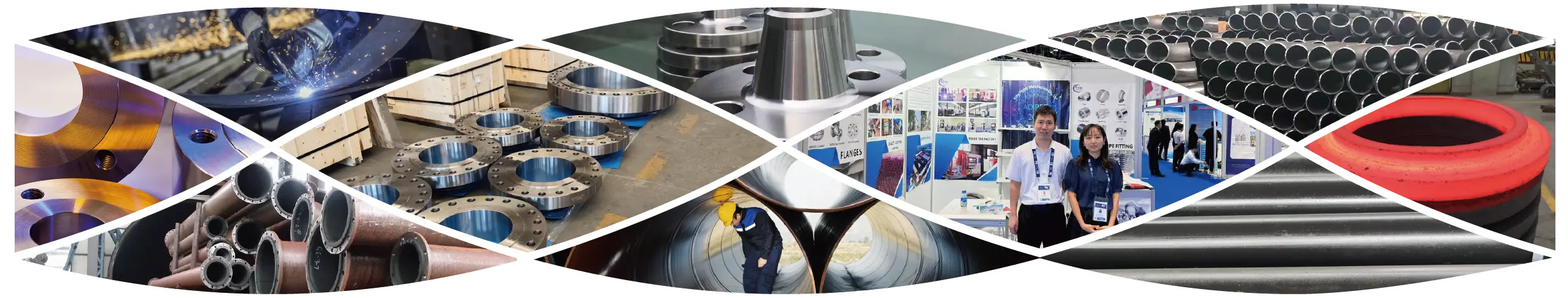

ANSI B16.47 Lapped Joint Flange

ANSI B16.9 Reducing Weld Neck Flange

ANSI B16.9 Weld-Neck-Flange

POPULAR FLANGE STYLES

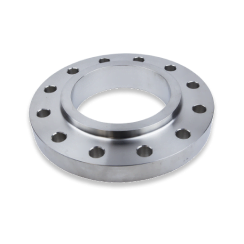

Weld Neck Flange

The weld neck flange is mainly a part that connects pipes to each other. Our weld neck flange has been recognized by many customers. If you need it, our company’s products are your best choice. Welcome everyone to communicate with Elite Piping Manufacture.

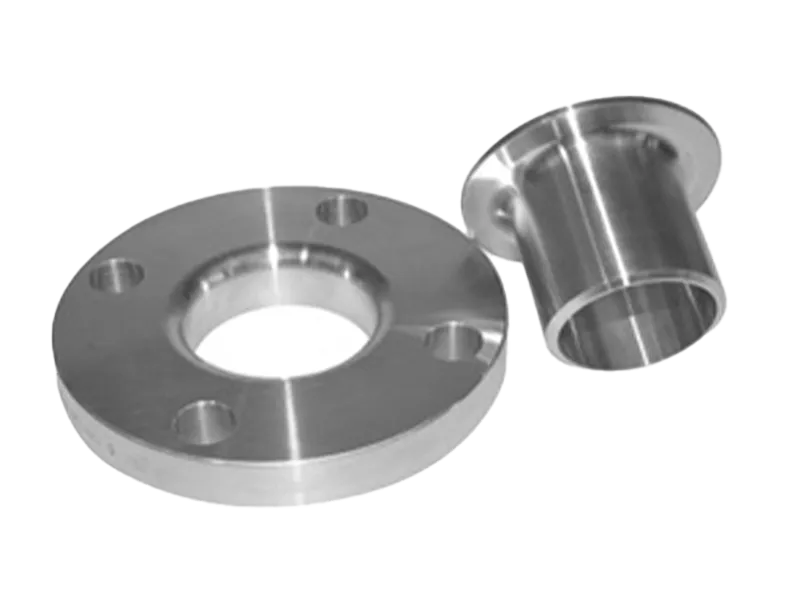

Slip On Flange

Slip on flange is also called lap welding flange. The connection between the flat welding flange and the pipe is to insert the pipe into the inner hole of the flange to the appropriate position, and then lap weld it.

Blind Flange

The real name of blind flange is blind plate, which is a connection form of flange. In fact, it is a flange without a hole in the middle. Its materials include carbon steel, alloy, stainless steel, plastic, etc. It is mainly used to seal the front end port of the pipeline.

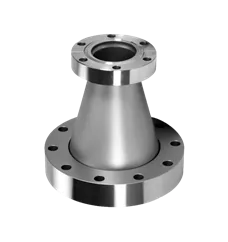

Reducing Flange

A reducing flange is a type of flange used in piping systems to connect pipes of different diameters. Unlike standard flanges that join pipes of the same size, reducing flanges have a larger bore on one end and a smaller bore on the other, allowing for a smooth transition between different pipe sizes.

Products

We also stock a wide variety of pipe fittings in all sizes and specifications.

Bend

View More

Cap

View More

Cross

View More

Reducer

View More

Stub end

View More

Tee

View More

Coupling

View More

HOW WE WORK

At Elite Piping Manufacture Co., Ltd., the manufacturing process begins with the careful selection of high-grade raw materials, which are then subjected to advanced forming techniques to create seamless and welded pipes. Utilizing state-of-the-art machinery, our skilled technicians perform precision cutting, bending, and welding to produce various fittings and custom piping solutions. Throughout the production stages, rigorous quality control measures, including non-destructive testing and inspection, ensure that each product meets stringent industry standards. The process is complemented by adherence to sustainable practices, minimizing environmental impact, and optimizing resource efficiency, culminating in reliable, high-performance piping products ready for global distribution.

EXHIBITION & ELITE PIPING

The globally renowned petroleum event—the 2024 Iran International Oil, Gas, Refining & Petrochemical Exhibition—opened grandly from May 8th to 11th. We are honored to participate in this Iranian exhibition. We entered the Iranian market in 2013 and have extensive project supply performance; Elite Piping is not only a professional pipe fitting manufacturer but also a very professional piping package and high-quality vendor. We provide carbon steel seamless pipes, LSAW pipes, alloy steel pipes, stainless steel seamless pipes, welded pipes, CS, CS, and SS fittings and flanges, gaskets, bolts and nuts, and valves. We provide customers with complete package quotations and supplies. With this strong supply chain advantage, we have gained the trust of many customers.

INDUSTRIES WE SERVE

Natural Gas Project

Both flanges and fittings are made from durable materials, guaranteeing the safe and efficient conveyance of gas through pipelines.

Pefinery Project

Flanges and pipe fittings are constructed from durable materials to withstand high pressures, temperatures, and corrosive environments found in refineries.

Power Generation Project

In power generation projects, the use of flanges and pipe fittings is essential for creating a robust and reliable piping system capable of handling the high pressures and temperatures typical in such environments.

Offshore Project

Flanges and pipe fittings are integral to the functionality of systems handling hydrocarbons, water injection, and various fluids critical to offshore oil and gas production.

Sewage Treatment Project

In sewage treatment projects, flanges and pipe fittings are designed to maintain flow efficiency while ensuring durability under harsh sewage conditions.

Petroleum Project

To ensure reliability and minimize the risks of leaks or failures that could jeopardize operational safety and environmental compliance, flanges and fittings are essential components in petroleum projects.

Latest News

CS Spectacle Flange Sent To Uzbekistan

Elite Piping Manufacture Co., Ltd. is well-known for providing high-quality flanges and pipe fittings solutions customized for a variety of […]Read More

4 Inch Flange Price

The 4 inch flange price can fluctuate based on various factors, including material type, flange design, manufacturing standards, and the supplier’s […]Read More

Flange Manufacturer In UAE

A flange manufacturer in UAE plays a crucial role in supporting the region’s growing industrial and infrastructure sectors, including oil […]Read More