In 2023, Elite Piping was assigned the substantial task of supplying a diverse assortment of A105 flanges, ranging from 1/2 inch to 48 inches, to the Iranian Central Oil Fields Company (ICOFC). This case study delves into the specifics of this important project, detailing the requirements, processes, challenges, and outcomes linked with the delivery of these essential A105 flanges sent to Iran. It highlights how Elite Piping managed the comprehensive supply of A105 flanges sent to Iran, addressing the unique needs of ICOFC, a prominent entity in Iran’s oil and gas sector.

Client Profile: ICOFC

The Iranian Central Oil Fields Company (ICOFC) is a key player in Iran’s oil and gas industry, responsible for the development and management of various oil fields nationwide. ICOFC’s activities are vital to Iran’s energy sector, encompassing exploration, drilling, and production. Due to the extensive and critical nature of their projects, ICOFC demands high-quality, dependable components to maintain the smooth functioning of their infrastructure. In this context, the A105 flanges sent to Iran were essential to meet these rigorous requirements and ensure the reliability of ICOFC’s operations.

Project Scope And Requirements Of A105 Flanges Sent To Iran

Order Specifications

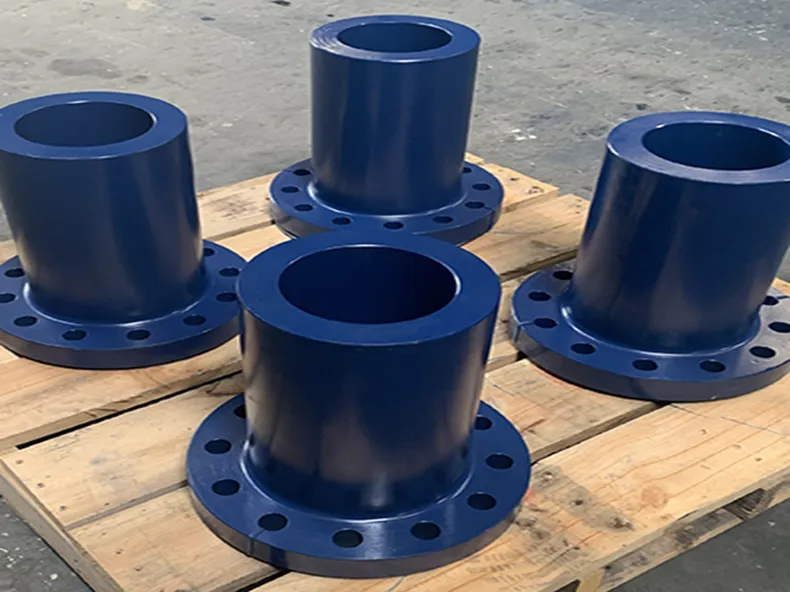

A105 carbon steel, complying with ASTM standards for high pressure and temperature service.

Flanges of various sizes, from 1/2 inch to 48 inches, covering a broad spectrum of piping needs.

The flanges needed to meet ANSI pressure classes, including Class 150, 300, and 600, to match the operational requirements of ICOFC’s infrastructure.

Quality Standards

Precision in dimensions was crucial to ensure proper fitting and performance.

High-quality surface treatment was needed to prevent corrosion and ensure a secure seal.

Each flange had to undergo a series of tests, including pressure tests and non-destructive testing, to validate its performance under operational conditions.

Challenges And Solutions

Ensuring the quality of the flanges amidst the large order volume was a significant challenge. Elite Piping addressed this by implementing stringent quality control measures, including multiple stages of inspection and testing. This comprehensive approach ensured that each flange met the required standards and specifications.

Meeting the delivery deadlines for such a large order required meticulous planning and coordination. Elite Piping’s logistics team efficiently managed the shipping and handling processes, ensuring that the flanges arrived on time despite any potential delays or logistical challenges.

ICOFC’s specific needs for various sizes and pressure ratings added complexity to the manufacturing process. Elite Piping successfully managed this by leveraging its expertise and flexibility in production, ensuring that all custom requirements were met without compromising on quality.

Impact On ICOFC’s Operations

- Operational Efficiency

- Safety And Compliance

- Strengthened Partnership

- Long-Term Benefits

The high-quality A105 flanges sent to Iran by Elite Piping greatly improved the operational efficiency of ICOFC’s infrastructure. The dependable performance of these A105 flanges sent to Iran ensured secure, leak-proof connections, which helped minimize downtime and reduce maintenance needs. As a result, ICOFC was able to concentrate on optimizing their operations and meeting their production goals.

The adherence to stringent quality standards and the use of A105 carbon steel ensured that the flanges met ICOFC’s safety and compliance requirements. The flanges performed reliably under high-pressure and high-temperature conditions, contributing to the overall safety and integrity of ICOFC’s oil field operations.

The successful completion of the project strengthened the partnership between Elite Piping and ICOFC. The prompt delivery of the A105 flanges sent to Iran, along with their high quality, highlighted Elite Piping’s dedication to customer satisfaction and its ability to manage complex, large-scale orders involving A105 flanges sent to Iran.

The durability and reliability of the A105 flanges sent to Iran offered long-term advantages for ICOFC. The performance of these A105 flanges sent to Iran under demanding conditions guaranteed the longevity of the infrastructure, decreasing the frequency of replacements and repairs. This not only resulted in cost savings but also improved the overall efficiency of ICOFC’s operations.

Elite Piping Manufacture Co., Ltd.’s delivery of 1/2″-48″ A105 carbon steel flanges to the Iranian Central Oil Fields Company (ICOFC) demonstrates the company’s expertise in providing high-quality components for critical applications. This project showcased Elite Piping’s capability to meet rigorous specifications, uphold strict quality standards, and ensure timely delivery of A105 flanges sent to Iran. The successful execution of this project not only enhanced ICOFC’s operational efficiency and safety but also reinforced the partnership between Elite Piping and a major player in Iran’s oil and gas sector. The case study highlights Elite Piping’s dedication to excellence and its pivotal role in supplying reliable and high-performance A105 flanges sent to Iran, supporting the global oil and gas industry.

GET IN TOUCH

Company:

Elite Piping Manufacture Co., Ltd.

Factory Address:

Office # 805, Building No. 6 Poly Metropolitan, Yongshum Town, Tongzhou District, Beijing, China.

Contact Person:

Michael

Contact Numbers:

+86 186 1829 1381

Email:

elite@elitepiping.com