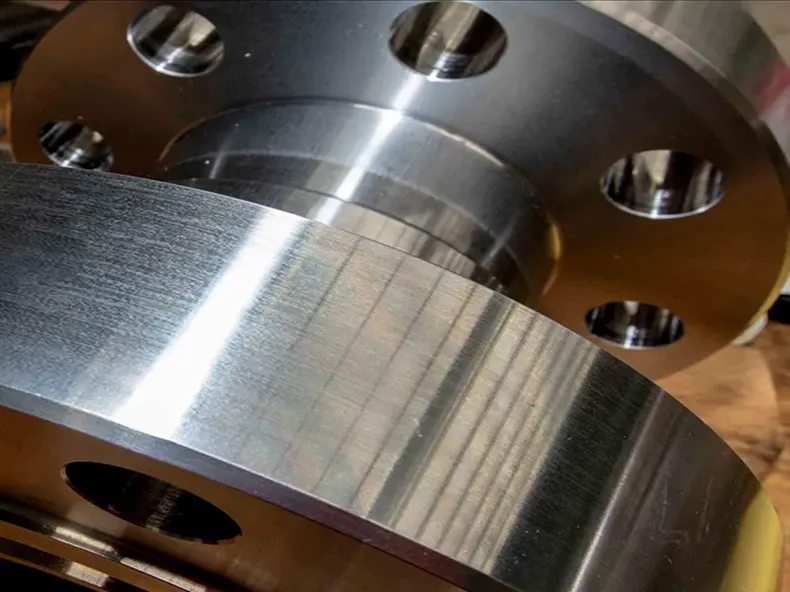

Elite Piping Manufacture Co., Ltd. achieved a significant milestone by successfully delivering 6″-16″ Alloy 625 flanges to ROO (ROOT Energy & Engineering Services) in 2023. This delivery of Alloy 625 flanges sent to Qatar showcased the company’s expertise in supplying high-performance piping solutions tailored for demanding applications.

The Alloy 625 flanges sent to Qatar were distinguished by their exceptional corrosion resistance and high-temperature strength, meticulously crafted to meet ROO’s rigorous specifications. Elite Piping’s dedication to quality and precision ensured that these Alloy 625 flanges not only adhered to industry standards but also effectively supported ROO’s critical operations in the energy sector, reinforcing Elite Piping’s reputation as a reliable supplier in the oil and gas industry.

Client Background

ROOT Energy & Engineering Services (ROO) is a leading player in the energy sector, known for offering engineering solutions and services for intricate oil and gas projects. Their operations frequently demand components that can withstand extreme conditions, such as extreme pressure, elevated temperatures, and corrosive conditions. For a significant project, ROO required high-performance Alloy 625 flanges capable of enduring these severe service conditions. Thus, the Alloy 625 flanges sent to Qatar were specifically chosen to meet these demanding requirements, ensuring reliability and performance under challenging conditions.

Project Requirements

ROO specified the requirement for Alloy 625 flanges in sizes from 6″ to 16″. The Alloy 625 flanges sent to Qatar are well-known for their exceptional resistance to corrosion, oxidation, and high temperatures. As a nickel-based superalloy with superior mechanical properties, these flanges are ideal for demanding applications. The order for Alloy 625 flanges sent to Qatar included a range of flange types, such as welding neck, slip-on, and blind flanges, all designed to meet industry standards and tailored to fulfill the specific needs of ROO’s project.

Alloy 625 Flanges Sent To Qatar Challenges Faced

Alloy 625 is challenging to work with due to its high strength and work hardening characteristics. Special tooling and techniques were required to handle the material without causing excessive wear on machinery or compromising precision.

The project had a strict timeline, and balancing the need for high-quality production with timely delivery posed a significant challenge. The manufacturing team had to optimize workflows and prioritize efficiency without sacrificing quality.

The transportation of the finished flanges to ROO’s project site required careful planning. Given the high value and critical nature of the components, special packaging and handling procedures were implemented to prevent damage during transit. Real-time tracking and secure shipping methods ensured the flanges arrived in optimal condition.

Delivery And Installation

The flanges were packaged using custom-designed crates and corrosion-resistant materials to protect them from environmental damage during shipping. Desiccants were included to prevent moisture-related issues.

The shipment was managed by a specialized logistics provider, ensuring secure and timely delivery. The shipping process included tracking systems and insurance coverage to mitigate any potential risks.

Upon arrival, Elite Piping provided technical support to ROO’s installation team. This included guidance on proper handling, installation procedures, and ensuring that the flanges were fitted correctly and functioned as intended.

Feedback From ROO

- Client Satisfaction

- Performance

- Future Collaboration

ROO expressed high levels of satisfaction with the quality of the flanges, praising the precision of the machining and the robustness of the material. The flanges met all technical specifications and performed reliably under operational conditions.

In service, the Alloy 625 flanges demonstrated excellent performance, maintaining their integrity in the harsh conditions of the project. ROO reported that the flanges contributed significantly to the success of the installation, providing the durability and performance required for their application.

Based on the successful outcome of this project, ROO indicated interest in continuing their partnership with Elite Piping for future projects. The positive feedback and the high performance of the Alloy 625 flanges reinforced the value of Elite Piping’s products and services.

The successful delivery of alloy 625 flanges sent to Qatar highlights Elite Piping Manufacture Co., Ltd.’s commitment to excellence in meeting the demanding requirements of the oil and gas industry. The project demonstrated the company’s capability to handle complex orders, navigate challenges, and deliver high-quality components that meet stringent industry standards. The positive feedback from ROO underscores the reliability and performance of Elite Piping’s products, establishing a strong foundation for ongoing and future collaborations in critical industrial applications.

GET IN TOUCH

Company:

Elite Piping Manufacture Co., Ltd.

Factory Address:

Office # 805, Building No. 6 Poly Metropolitan, Yongshum Town, Tongzhou District, Beijing, China.

Contact Person:

Michael

Contact Numbers:

+86 186 1829 1381

Email:

elite@elitepiping.com