In 2017, Elite Piping Manufacture Co., Ltd. successfully dispatched a full range of 1/2″ to 30″ carbon steel ASTM A234 WPB fittings to Algeria for ENTREPOSE, a prominent global engineering and construction firm. This delivery of carbon steel ASTM A234 WPB fittings sent to Algeria showcased Elite Piping’s capability in meeting the needs of major industrial clients.

This project involved the precise fabrication and timely shipment of various fittings, including elbows, tees, reducers, etc., all manufactured to meet stringent ASTM A234 WPB standards. The high-quality components were essential for ensuring the integrity and performance of ENTREPOSE’s piping systems across multiple sectors, including oil and gas and chemical processing.

The successful execution of this order demonstrated Elite Piping’s commitment to excellence in product quality and logistical coordination, reinforcing their reputation as a reliable partner in the industry.

Project Overview Of Carbon Steel ASTM A234 WPB Fittings Sent To Algeria

ENTREPOSE is a prominent entity in the engineering and industrial services sector, offering solutions across industries like oil and gas, petrochemicals, and energy. The company is recognized for its proficiency in managing complex projects that demand high standards of quality and reliability, exemplified by the carbon steel ASTM A234 WPB fittings sent to Algeria. These fittings reflect ENTREPOSE’s commitment to delivering superior performance and dependability in its projects.

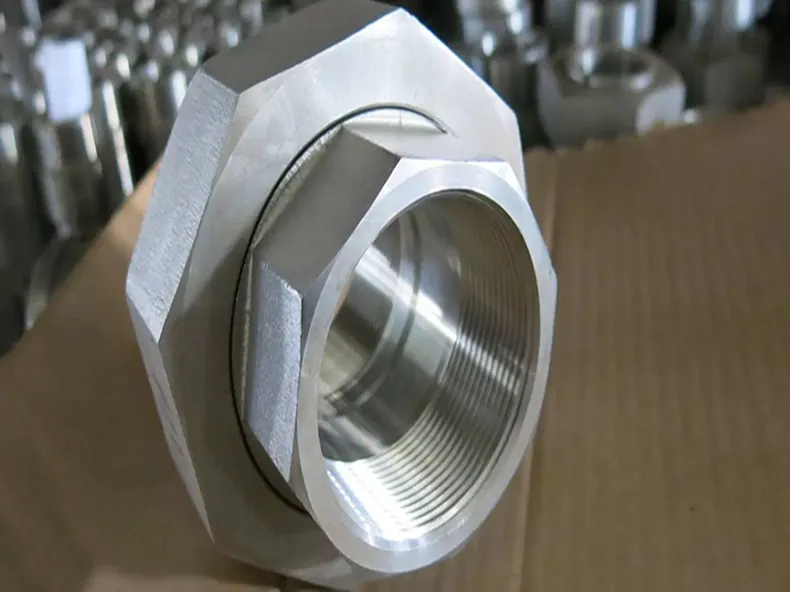

The carbon steel ASTM A234 WPB fittings sent to Algeria were crafted from a material known for its strength and durability in high-pressure and high-temperature applications. These carbon steel ASTM A234 WPB fittings were crucial for building a resilient piping system designed to withstand the challenging conditions of ENTREPOSE’s project.

The order for carbon steel ASTM A234 WPB fittings sent to Algeria encompassed a diverse range of sizes, from 1/2″ to 30″. This variety highlights the extensive capabilities of Elite Piping in supplying fittings that meet different needs within a single project. The range of sizes for the carbon steel ASTM A234 WPB fittings sent to Algeria ensured compatibility with various piping systems and project specifications.

Challenges And Resolutions

One of the challenges associated with this shipment was managing the size variability of the fittings, ranging from 1/2″ to 30″. Ensuring that all sizes were accurately manufactured, packaged, and transported required careful planning and coordination. The resolution involved detailed tracking and monitoring throughout the manufacturing and logistics processes to address any discrepancies or issues promptly.

Maintaining consistent quality across the wide range of fittings posed another challenge. The resolution involved implementing stringent quality control measures at every stage of the production process, from raw material inspection to final testing.

Coordinating the delivery of such a diverse range of fittings required effective communication and collaboration among various stakeholders. The resolution involved establishing clear communication channels, detailed scheduling, and proactive problem-solving to address any logistical issues that arose.

Impact On ENTREPOSE

- Operational Efficiency

- Project Success

- Customer Satisfaction

The timely delivery of the Carbon Steel ASTM A234 WPB fittings had a significant impact on ENTREPOSE’s operations. The fittings were used in various projects, including pipeline installations and maintenance activities. The high-quality components ensured that the piping systems were assembled and maintained effectively, contributing to the overall efficiency and reliability of the projects.

ENTREPOSE’s ability to execute its projects successfully was greatly enhanced by the quality and reliability of the fittings. The use of ASTM A234 WPB fittings ensured that the piping systems could withstand high pressures and temperatures, which was critical for the success of the projects. The seamless integration of these fittings into the existing systems also facilitated smooth operations and minimized downtime.

The successful delivery and performance of the fittings contributed to ENTREPOSE’s satisfaction with the supplier. The adherence to specifications, timely delivery, and quality assurance measures provided a positive experience for ENTREPOSE, reinforcing the supplier’s reputation for reliability and excellence.

The case involving 1/2″ to 30″ carbon steel ASTM A234 WPB fittings sent to Algeria for ENTREPOSE illustrates the significance of precision, quality, and coordination in industrial supply. From the initial inquiry through to the final delivery, every aspect was carefully managed to ensure that the carbon steel ASTM A234 WPB fittings sent to Algeria met the highest standards of performance and reliability. The successful use of these fittings in ENTREPOSE’s project underscores the crucial role that high-quality components play in achieving project objectives and maintaining system integrity. This case study highlights the importance of effective collaboration and a commitment to excellence in fulfilling the demands of complex industrial applications.

GET IN TOUCH

Company:

Elite Piping Manufacture Co., Ltd.

Factory Address:

Office # 805, Building No. 6 Poly Metropolitan, Yongshum Town, Tongzhou District, Beijing, China.

Contact Person:

Michael

Contact Numbers:

+86 186 1829 1381

Email:

elite@elitepiping.com