Compact flanges are specialized pipe flanges designed to minimize space and weight while maximizing strength and reliability. They feature a compact profile with a sealing face that integrates into the flange itself, eliminating the need for separate gaskets. This design decreases the overall dimensions and weight of the flange assembly compared to traditional flanges, making compact flanges ideal for applications where space is limited or weight considerations are critical. If you are interested in our compact flanges, please contact us.

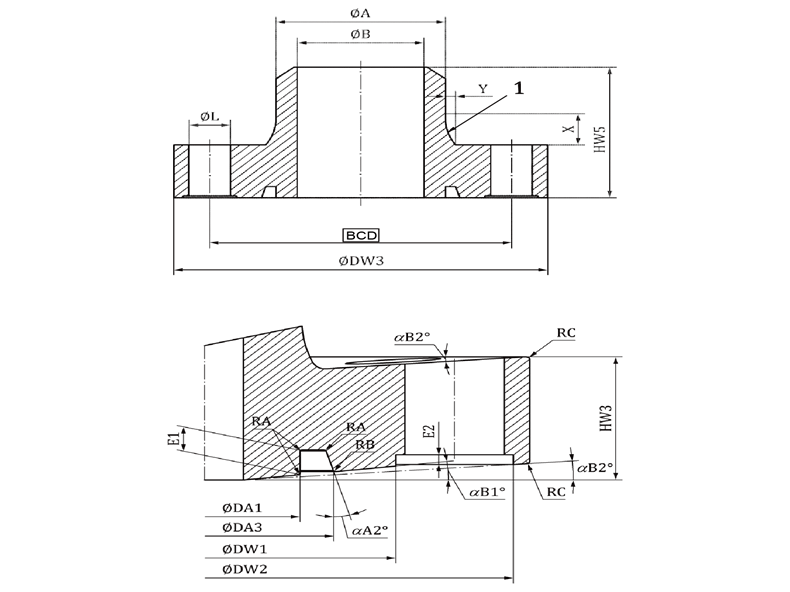

Overall Dimensions Of Compact Flange Dimensions

Compact flanges generally have a smaller outer diameter compared to standard flanges of the same nominal pipe size (NPS). For example, a compact flange with an NPS 4 size may have an outer diameter of approximately 7 inches (177.8 mm), whereas a standard ANSI flange of the same size could have a larger outer diameter.

The overall height of compact flanges is minimized to reduce the space required for installation. For instance, a compact flange with an NPS 4 size might have an overall height of around 1.5 inches (38.1 mm), ensuring a compact profile while maintaining structural integrity and pressure containment.

The bolt circle diameter refers to the diameter of the circle passing through the center of all bolt holes in the flange. Compact flanges typically have a reduced BCD compared to standard flanges, optimizing bolt alignment and reducing the footprint of the flange assembly.

Sealing Face Dimensions Of Compact Flange Dimensions

Sealing Face Dimensions Of Compact Flange Dimensions

The sealing face of a compact flange is typically machined directly into the flange itself, creating a smooth and flat surface that mates with the sealing face of the adjoining flange or equipment. This sealing surface area is crucial for preventing leaks and maintaining pressure containment.

Width And Depth Of Sealing Groove

Compact flanges feature a sealing groove that accommodates the compression of the metal-to-metal contact between the sealing faces. The dimensions of this groove, including its width and depth, are designed to ensure sufficient contact pressure and sealing performance under operating conditions.

Bolt Hole Pattern And Size Of Compact Flange Dimensions

Bolt Hole Size

Compact flanges typically accommodate standard bolt sizes such as 3/4 inch (19 mm) or 1 inch (25 mm) diameter bolts. The size of the bolt hole is critical for ensuring sufficient bolt strength and load distribution to withstand operating pressures and forces.

Number of Bolt Holes

Compact flanges typically have fewer bolt holes compared to traditional flanges of the same nominal size. This reduction in bolt holes contributes to the compact design and efficient use of space.

Compact Flanges In Different Sizes

Small Sizes (NPS 1/2 to NPS 2)

Compact flanges in smaller sizes are typically used in instrumentation lines, small-bore piping systems, and applications where space efficiency is crucial. These sizes often range from NPS 1/2 (DN 15) to NPS 2 (DN 50), catering to lower flow rates and pressure requirements in compact environments.

Medium Sizes (NPS 3 to NPS 8)

Medium-sized compact flanges cover a broader range of industrial applications, including oil and gas pipelines, petrochemical plants, and refineries. Sizes commonly range from NPS 3 (DN 80) to NPS 8 (DN 200), providing effective sealing and pressure containment while optimizing space and weight compared to traditional flanges.

Large Sizes (NPS 10 and above)

Compact flanges in larger sizes are utilized in critical applications such as offshore platforms, subsea pipelines, and large-scale industrial facilities. These sizes typically start from NPS 10 (DN 250) and can extend to NPS 24 (DN 600) or even larger, offering robust performance under high-pressure and challenging operating conditions.

Elite Piping Manufacture Co., Ltd., a prominent supplier in the industrial piping sector, has established ourselves as a leading manufacturer of compact flanges renowned for our precision engineering and reliability. Specializing in a diverse array of piping products, Elite Piping Manufacture Co., Ltd. excels in producing compact flanges that meet stringent international standards, catering primarily to the oil and gas, petrochemical, power generation, and offshore industries.

At the core of Elite Piping Manufacture Co., Ltd.’s offerings is our commitment to quality and innovation. Our compact flange dimensions are engineered with meticulous attention to detail, ensuring optimal performance and durability in demanding environments. These flanges are designed to provide a robust sealing solution, capable of withstanding high pressures and temperatures prevalent in industrial applications.

Quality assurance is a cornerstone of Elite Piping Manufacture Co., Ltd.’s manufacturing process. Each compact flange undergoes rigorous testing and inspection protocols to ensure adherence to industry standards and customer specifications. By following these rigorous quality control measures, the company ensures that our products consistently meet or exceed performance expectations.

In addition to our dedication to quality, Elite Piping Manufacture Co., Ltd. emphasizes customer satisfaction through responsive service and tailored solutions. Their skilled team works closely with clients to grasp their distinct needs and deliver customized flange solutions that optimize operational efficiency and reliability.

Beyond our product offerings, Elite Piping Manufacture Co., Ltd. distinguishes ourselves through a commitment to sustainability and environmental stewardship. We employ advanced manufacturing technologies and practices that minimize waste and energy consumption, contributing to a more sustainable industrial ecosystem.

The company’s reputation for excellence extends globally, with a strong presence in markets across Asia, Europe, North America, and beyond. This extensive reach is supported by a robust distribution network and strategic partnerships that ensure prompt delivery and comprehensive support for clients worldwide.

GET IN TOUCH

Company:

Elite Piping Manufacture Co., Ltd.

Factory Address:

Office # 805, Building No. 6 Poly Metropolitan, Yongshum Town, Tongzhou District, Beijing, China.

Contact Person:

Michael

Contact Numbers:

+86 186 1829 1381

Email:

elite@elitepiping.com