Elite Piping Manufacture Co., Ltd. has positioned itself as a reliable supplier of high-quality flanges and pipe fittings across diverse industries. In 2019, the company executed a major project involving the delivery of SS A304 pipe fittings sent to Canada, ranging from 1 inch to 3 inches in size, for SNC-LAVALIN, a renowned global engineering firm. This case study outlines the particulars of the order, the challenges encountered, and the strategies implemented to ensure the successful delivery of the SS A304 pipe fittings sent to Canada.

Requirements Of SS A304 Pipe Fittings Sent To Canada

The fittings needed to adhere to international standards such as ASTM and ASME to ensure quality and reliability.

Given the unique design of the facility, several custom fittings were required that deviated from standard sizes and specifications.

The project timeline was tight, requiring efficient manufacturing and logistics processes to meet deadlines.

Each fitting had to undergo thorough testing to ensure it met the mechanical and structural integrity required for the application.

Production Process

- The engineering team collaborated with SNC-LAVALIN to finalize the designs and specifications of the fittings. This phase included creating detailed technical drawings and assessing the required tolerances;

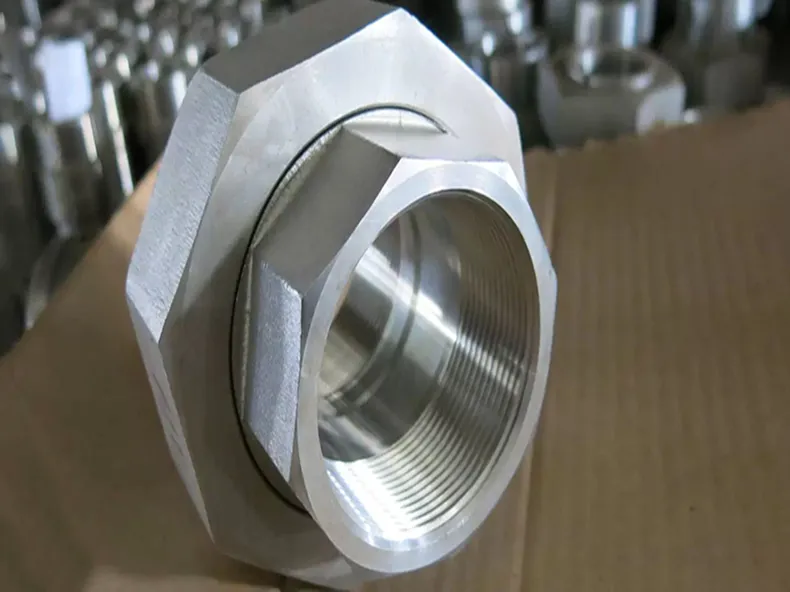

- Once the designs were approved, the stainless steel A304 material was prepared. This involved cutting the raw material into appropriate lengths and shapes for manufacturing;

- The fittings were fabricated using advanced welding techniques, ensuring strong and durable connections. The welding process was carried out by certified welders who adhered to strict quality standards;

- After fabrication, the fittings underwent surface finishing to enhance their corrosion resistance. This process included polishing and passivation to ensure a smooth surface;

- To assess the fittings' ability to withstand high pressure without leaking;

- To verify that the fittings met the specified dimensions and tolerances;

- To check for any defects or imperfections in the surface.

Challenges Faced

The requirement for custom sizes presented a challenge regarding manufacturing time and resource allocation. Elite Piping had to guarantee that the SS A304 pipe fittings sent to Canada were produced without sacrificing quality or surpassing deadlines.

Global supply chain disruptions impacted the availability of raw materials. To address this, Elite Piping collaborated closely with suppliers to mitigate delays and secure a consistent supply of the stainless steel required for the SS A304 pipe fittings sent to Canada.

Coordinating the transportation of the SS A304 pipe fittings sent to Canada to the project site required careful planning. Elite Piping needed to navigate potential obstacles, such as permits and scheduling conflicts, to ensure timely delivery.

Logistics And Delivery

Logistical Planning

Elite Piping collaborated closely with logistics partners to organize the transport of the SS A304 pipe fittings sent to Canada. Due to the size of the order and the necessity for careful handling, specialized transportation was arranged to ensure no damage occurred during transit.

Tracking And Communication

Throughout the logistics process for the SS A304 pipe fittings sent to Canada, Elite Piping maintained open lines of communication with SNC-LAVALIN, offering updates on the shipment status and expected delivery times. This transparency built trust and ensured that SNC-LAVALIN was informed at every stage of the process.

Successful Installation And Feedback

The installation of the SS A304 pipe fittings sent to Canada proceeded smoothly, thanks to the precision manufacturing that guaranteed a perfect fit. The project team noted that the fittings were easy to handle and install, which contributed to an efficient assembly process.

Post-installation feedback indicated that the SS A304 pipe fittings sent to Canada performed exceptionally well in their intended application. They demonstrated the required resistance to corrosive fluids, maintained structural integrity under pressure, and met the thermal requirements of the system.

Client Satisfaction

- Quality Assurance

- Timeliness

- Communication And Support

The quality of the SS A304 fittings exceeded expectations, affirming Elite Piping’s reputation as a reliable supplier.

Elite Piping’s ability to meet tight delivery deadlines was praised, as it enabled SNC-LAVALIN to adhere to their project schedule without delays.

Continuous communication and support from Elite Piping’s team helped streamline the process, ensuring that any questions or concerns were promptly addressed.

The project involving the supply of 1-inch to 3-inch SS A304 pipe fittings sent to Canada to SNC-Lavalin showcases Elite Piping Manufacture Co., Ltd.’s capabilities in delivering high-quality piping solutions tailored to meet the stringent requirements of large-scale industrial applications. Through advanced manufacturing processes, rigorous quality control, and efficient logistics, Elite Piping demonstrated its role as a trusted partner in the global engineering and construction sector.

This case not only highlights Elite Piping’s commitment to excellence but also emphasizes the importance of strong collaborations in delivering successful outcomes in complex projects. The successful execution of this project positions Elite Piping favorably for future opportunities involving SS A304 pipe fittings sent to Canada, further solidifying its reputation as a leading supplier of stainless steel pipe fittings in the industry.