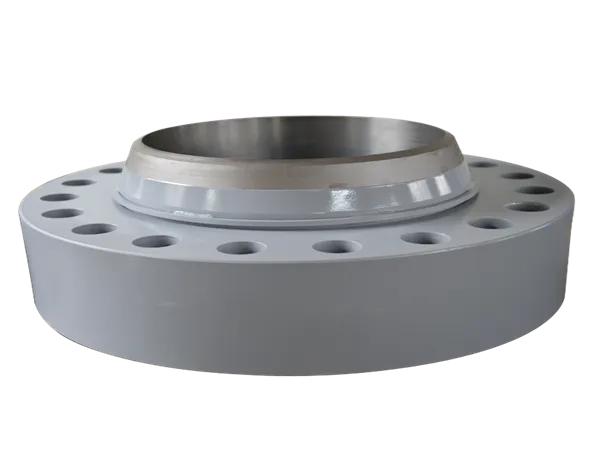

Swivel Flange

The swivel flange is similar in structure to the loose tube flange. The difference is that the swivel flange can be used in higher-pressure environments. It is currently mainly used in submarine pipelines and other occasions. Elite Piping Manufacture Co specializes in swivel flange. Our products are of high quality, and our services are in place. We are your best choice. You are welcome to communicate with us on related matters at any time.

REFINE BY

- Flange Manufacturer

- Flange standard

- Welding Neck Flange

- Stainless steel Flange

- Carbon & Alloy steel Flange

- Blind Flange

- Lap Joint Flange

- Orifice Flange

- Threaded Flange

- Swivel Ring Flange

- Reducing Flange

- Slip-On Flange

- Spectacle Blind Flange

- Compact Flange

- 1/2" (24)

- 3/4" (24)

- 1" (24)

- 1-1/4" (24)

- 1-1/2" (24)

- 2" (25)

- 2-1/2" (24)

- 3" (24)

- 4" (20)

- 4" (20)

- 304L (179)

- 316L (179)

Swivel Flange Models

The Structures Of Swivel Flange

The rotating ring flange can adjust the position of the bolt holes on the flange ring through 360° rotation, and the position of the bolt holes can be adjusted on-site to achieve an accurate connection.

Swivel Flange

The swivel flange has two main structures: forged connectors and a swivel ring. The forged swivel ring is designed to be a counter-neck or other type of matching flange. The swivel flange has a retaining ring with a forged connection to hold the swivel ring in place.

The Application Of Swivel Flange

At present, rotating ring flanges are widely used in marine pipelines. They solve the problem of difficult alignment with bolt holes during offshore flange installation.

The swivel flange is a sealing device that connects the rotating roller and the fixed pipe. It ensures the inflow and outflow of steam, thermal oil, water, coolant, hydraulic oil, and other media with specific pressure and temperature while ensuring that the fixed pipe and the rotating roller are connected.

There is no leakage between long-term sealing. Rotary joints have a wide range of applications and play a key role in papermaking, metallurgy, machine tools, power generation, petroleum, rubber, plastics, textiles, printing and dyeing, pharmaceuticals, cigarettes, food, feed processing and other industries.

The pressure grade of the rotating ring flange is generally CLASS 150 to CLASS 2500. Pressure, temperature ratings and basic dimensions are also the same as ASME B16.5 and MSS SP44 flanges, making it easy to mate with standard butt weld flanges.

The standard material of the swivel flange is ASME A105, and the thickness of the welded end can be adjusted for higher yield-strength pipes. Flanges can also be made of higher yield-strength materials, such as ASTM A694 or ASTM A707, and can be supplied to customer specifications.

ASME B16.5, ASME B31.1, ASME B31.3, and MSS SP44 do not have industry standards specifically applicable to the design and manufacture of swivel ring flanges. The design standards of swivel ring flanges of different manufacturers vary greatly. Most refer to ASME or MSS standards. Of course, to connect with standard flange connections, most manufacturers’ design dimensions comply with flange standards such as ASME B16.5, but other relevant design parameters are currently basically determined by the manufacturers themselves.

The Connection Of Swivel Flange

The connection of the rotating flange is actually achieved by welding, but this flange is a rotating ring on the accessory component that has been welded to the pipe. Then the accessory component and the gasket are pressed together through the connecting bolt to achieve sealing. It does not come into contact with the medium itself.

The Advantages Of Swivel Flange

The advantages of this type of flange connection are that the flange can be rotated, it is easy to center the bolt holes, it is easy to install on large-diameter pipes, and it is also suitable for places where the pipes need to be frequently disassembled for cleaning and inspection.

The material of the flange accessory components is consistent with the pipe material. Still, the flange material can be different from the pipe material (most flange materials are Q235 and Q255 carbon steel), so it is more suitable for pipelines transporting corrosive media.

The swivel flanges have higher pressure resistance and are generally suitable for connecting high-pressure pipelines.

Steam leakage from the rotary joint insulation sleeve flange often occurs at the paper machine site. Steam leakage brings energy waste and safety hazards and is more likely to cause the leaked steam to enter the bearing chamber through the dryer bearing pad and mix into the thin oil.

This causes the moisture in the thin oil station to increase, destroys the lubrication function of the thin oil, causes early wear and failure of the dryer cylinder bearings, and causes heavy losses.

The swivel insulator and hub flange assembly consists of a sealing gasket and one or two O-rings in the hub flange. Failure of any one of these seals can result in steam leakage. A tear hole is designed on the journal flange, which is the outlet for steam leakage.

Methods For Determining Swivel Flange Leakage

The leaking steam will make a sound, and you can hear it making an indirect or continuous whooshing sound with each rotation.

You will see white leaking steam swirling near the flange of the heat shield. pulvinar dapibus leo.

If the pressure of the leaking steam is very high, and you may only hear a high-frequency squeal but not see anything, you may attach a piece of paper to a pole and lift it close to the swivel joint. With each revolution, the steam hits the paper, causing wobbles.

Causes Of Leakage Of Swivel Flange

- The design of the heat insulation sleeve flange or the shaft head flange is unreasonable.

- Flange gasket design is unreasonable or of poor quality.

- The O-ring seal is improperly selected, or the material is prone to aging.