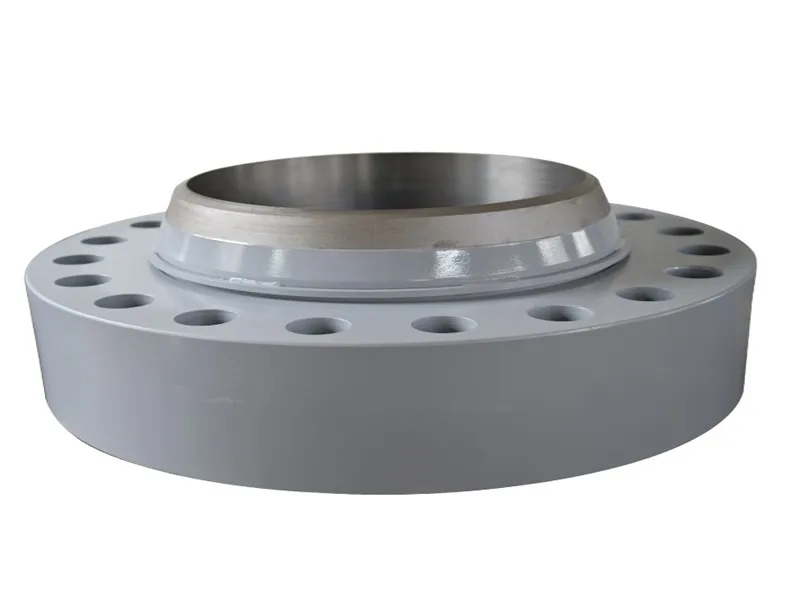

The difference between alloy steel flange and carbon steel flange is rooted in their composition and characteristics. Alloy steel flanges are crafted from carbon steel combined with alloying elements such as chromium, nickel, or molybdenum, which significantly boost their strength, hardness, and ability to resist corrosion and high temperatures. This makes them ideal for use in demanding environments like high-pressure and high-temperature applications.

In contrast, carbon steel flanges consist mainly of iron and carbon, providing good strength and machinability at a lower cost, but with less resistance to corrosion and high temperatures when compared to alloy steel. As a result, the difference between alloy steel flange and carbon steel flange means that carbon steel flanges are better suited for less severe conditions, whereas alloy steel flanges excel in more challenging industrial settings.

Advantages And Disadvantages About The Difference Between Alloy Steel Flange And Carbon Steel Flange

Carbon Steel Flanges

Advantages

Carbon steel flanges are generally more affordable than alloy steel flanges due to the lower cost of raw materials and simpler manufacturing processes.

Carbon steel is easier to machine and fabricate, which can result in lower production costs and quicker turnaround times.

Carbon steel flanges are widely available and come in various standard sizes and specifications, making them readily accessible for many applications.

Disadvantages

Carbon steel flanges are prone to corrosion, particularly in aggressive environments, which can lead to premature failure and increased maintenance costs.

They have limited tolerance for high temperatures and may not perform well in applications involving extreme thermal conditions.

Compared to alloy steel flanges, carbon steel flanges have lower strength and may not be suitable for high-pressure applications.

Alloy Steel Flanges

Advantages

Alloy steel flanges offer superior strength, hardness, and corrosion resistance, making them ideal for demanding applications in harsh environments.

They can withstand higher temperatures and extreme conditions, which is beneficial for applications in power generation, petrochemical industries, and aerospace.

The improved mechanical properties and resistance to corrosion contribute to the durability and longer service life of alloy steel flanges.

Disadvantages

Alloy steel flanges are more expensive due to the cost of alloying elements and the complex manufacturing processes involved.

The presence of alloying elements can make alloy steel more challenging to machine and fabricate compared to carbon steel, potentially increasing production time and costs.

Alloy steel flanges may be over-specification for applications that do not require their enhanced properties, leading to unnecessary expense.

Cost And Economic Considerations

Carbon steel flanges are generally more cost-effective compared to alloy steel flanges. Their lower material cost and simpler manufacturing processes contribute to their affordability. They are a popular choice for projects with budget constraints or where the performance requirements are less demanding.

Alloy steel flanges are more expensive due to the cost of alloying elements and the more complex manufacturing processes. However, their superior performance and durability can lead to lower maintenance and replacement costs over the long term. For critical applications where performance and reliability are paramount, the investment in alloy steel flanges is often justified.

Considerations For Selection

- Application Requirements

- Material Properties

- Cost Constraints

- Industry Standards

- Maintenance And Longevity

Determine the specific requirements of the application, including temperature, pressure, and exposure to corrosive agents. Alloy steel flanges are preferred for demanding environments, while carbon steel flanges are suitable for less severe conditions.

Evaluate the mechanical properties, such as strength, ductility, and hardness, to ensure the flange meets the performance requirements. Alloy steel flanges offer enhanced properties compared to carbon steel flanges.

Consider the budget for the project and weigh the cost of the flanges against their performance and durability. Carbon steel flanges offer a cost-effective solution, while alloy steel flanges provide superior performance at a higher cost.

Ensure that the selected flanges meet relevant industry standards and codes, such as ASTM, ANSI, or ISO, to ensure compatibility with other components and compliance with regulatory requirements.

Evaluate the expected lifespan of the flanges and the associated maintenance requirements. Alloy steel flanges typically offer longer service life and reduced maintenance compared to carbon steel flanges.

Elite Piping Manufacture Co., Ltd. is a leading manufacturer specializing in both alloy steel flanges and carbon steel flanges, offering a comprehensive range of products to meet diverse industrial needs. Understanding the difference between alloy steel flange and carbon steel flange is crucial for selecting the right materials for your applications, and Elite Piping excels in providing solutions tailored to these differences.

The difference between alloy steel flange and carbon steel flange lies in their composition, with alloy steel flanges incorporating additional elements like chromium, nickel, and molybdenum to enhance strength and corrosion resistance, making them suitable for more demanding environments.

On the other hand, carbon steel flanges, made primarily of iron and carbon, are cost-effective and versatile but offer limited resistance to harsh conditions. Elite Piping ensures that clients receive expert guidance on the difference between alloy steel flange and carbon steel flange, helping them make informed decisions for optimal performance and durability in their projects.

GET IN TOUCH

Company:

Elite Piping Manufacture Co., Ltd.

Factory Address:

Office # 805, Building No. 6 Poly Metropolitan, Yongshum Town, Tongzhou District, Beijing, China.

Contact Person:

Michael

Contact Numbers:

+86 186 1829 1381

Email:

elite@elitepiping.com