Elite Piping Manufacture Co., Ltd.’s main business is the supply of types of flanges used in oil and gas industry. The following article describes in detail the corresponding flange types we can provide. Types of flanges used in the oil and gas industry are as follows.

Stainless Steel Flange

-One Of Types Of Flanges Used In Oil And Gas Industry

A stainless steel flange, also known as a flange plate or flange plate, is the connecting component between the pipe end and the valve. Both sides of the flange are connected to the pipe end. The flange itself has holes, and the flanges at both ends pass through the holes. Tighten to connect pipes and prevent leaks.

Advantage

Stainless steel flanges are widely used as types of flanges used in oil and gas industry, transportation and processing. Due to its good ductility and elasticity, corrosion resistance, and strong wear resistance, it is widely used in oil pipe and gas pipe connections.

Application Occasions

Stainless steel flanges are safe, reliable, hygienic, environmentally friendly, economical, and applicable in high-quality drinking water systems, hot water systems, and water supply systems that prioritize safety and hygiene.

It is a new type of energy-saving and environmentally friendly excellent water supply material that can improve water quality and people’s quality of life.

Installation Method

When installing stainless steel flanges, they should be smooth and clean, and attention should be paid to removing oil stains and rust. When installing stainless steel flanges, be sure to choose a suitable gasket. The gasket must have aging resistance, oil resistance, and excellent mechanical strength. When installing stainless steel flange joints, choose gaskets of different sizes to ensure correct installation.

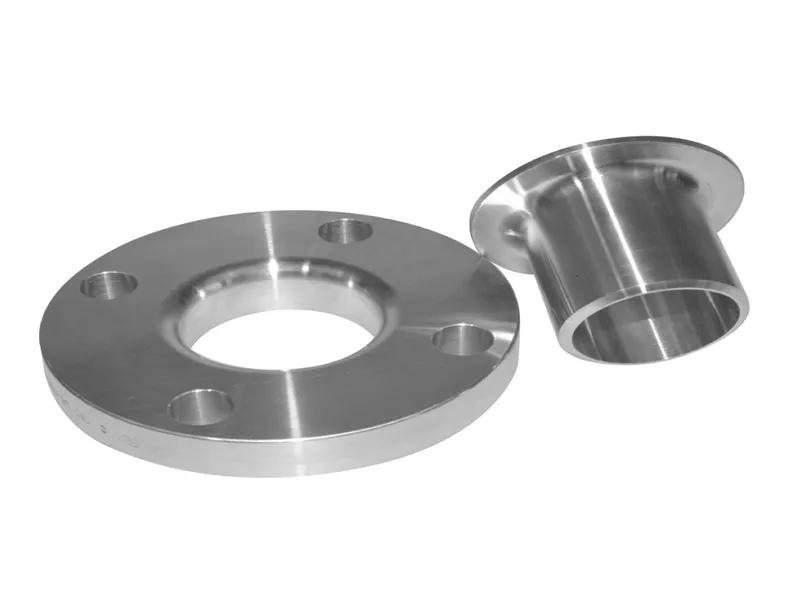

Socket Weld Flange

-One Of Types Of Flanges Used In Oil And Gas Industry

Socket welding flange refers to types of flanges used in oil and gas industry in which the end of the pipe is inserted into the flange ring step and welded on the pipe’s end and outside. There are two types: with neck and without neck.

Advantage And Application Occasions

The flange with the neck tube has good rigidity, small welding deformation, and good sealing performance. It can be used in situations where the pressure is 1.0~10.0MPa. Type B flange for containers is also a socket welding flange and is used in situations with high sealing requirements.

Installation Method

- Before installing the flange, check the flange sealing surface and gasket to ensure that there are no defects that affect the sealing performance, and remove the protective grease on the flange sealing surface;

- The bolts connecting the flange should be able to penetrate freely

- The installation direction and exposed length of flange bolts should be consistent;

- Tighten the nuts by hand to ensure that the nuts can rotate smoothly on the studs;

- The flange installation cannot be deflected, and the parallelism of the flange sealing surface must meet requirements.

Blind Flange

-One Of Types Of Flanges Used In Oil And Gas Industry

The real name of blind flange is blind plate, which is a connection form of flange. Its materials include carbon steel, alloy, stainless steel, plastic, etc. It is mainly used to seal the front end port of the pipeline.

Advantage

It has good sealing properties and can act as isolating, cutting, and sealing. Often used as a means of constant isolation when completely separated. Blind boards are solid boards with handles. Generally speaking, flange blind plates are more convenient as an isolation system used under normal conditions. Yellow orifice rings can be used to fill blind mounting gaps on pipes.

Application Occasions

Blind flanges can be used to isolate production media and prevent leakage due to loose closing of stop valves, which can affect production and even cause accidents. Blind flanges are installed at equipment connections, before and after stop valves, or between two flanges where isolation is required.

Installation Method

- Minimize the number of blind plates while meeting production process requirements;

- When setting blind plates, we must indicate normally open or normally closed;

- Whether the blind plate is set upstream or downstream of the shut-off valve should be determined based on the cutting effect, safety and process requirements.

Threaded Flange

-One Of Types Of Flanges Used In Oil And Gas Industry

Threaded flange is a non-welded flange that processes the inner hole of the flange into pipe threads and connects it with threaded pipes.

Advantage

Compared with flat welding flanges or butt welding flanges, threaded flanges are easier to install and maintain,and can be used for some pipelines where welding is not allowed on site. Alloy steel flanges have high strength and can meet the strength required for production, but their welding performance is poor and they are generally not easy to weld. Threaded flanges can also be selected.

Application Occasions

It is recommended not to use threaded flanges to avoid leakage when the pipe temperature changes rapidly or when the temperature is higher than 260°C and lower than -45°C.

There are threads on the inside of the flange. When connecting, the threaded flange needs to be connected to the external thread of the pipe. It is a non-welded flange with convenient installation and maintenance characteristics. It can be used in some occasions where welding is not suitable, but it is suitable for larger-diameter, low-pressure pipeline connections.

Loose Flange

-One Of Types Of Flanges Used In Oil And Gas Industry

The connection of the loose sleeve flange is actually achieved by welding, but this flange is loosely sleeved on the accessory component that has been welded to the pipe, and then the accessory component and the gasket are pressed tightly through the connecting bolt to achieve sealing. The orchid (i.e. loose sleeve) itself does not contact the medium.

Advantage And Application Occasions

The advantage of this type of flange connection is that the flange can be rotated, easy to center the bolt holes, easy to install on large-diameter pipes, and also suitable for places where the pipes need to be frequently disassembled for cleaning and inspection. The material of its flange accessory components is consistent with the pipe material, but the flange material can be different from the pipe material, so it is more suitable for pipelines transporting corrosive media.

Installation Method

These types of flanges used in oil and gas industry are not directly welded to the pipe, but uses the pipe flange or welding ring as the sealing contact surface. The loose flange plays a fastening role. It is mostly used for non-ferrous metals such as copper, aluminum and lead, as well as stainless and acid-resistant on steel pipes.

Welding Neck Flange

-One Of Types Of Flanges Used In Oil And Gas Industry

Welding flange is also called high neck flange. The flange plate is circular and protruding. When connecting, the two flanges need to be butted and butt welded. Bolts and nuts are usually used for fixation. It is suitable for pipelines under high pressure and high temperature. connect.

Advantage And Application Occasions

It is used in pipelines to match the types of flanges used in oil and gas industry on equipment (instruments, valves, pumps, other equipment, etc.). The shape of the butt welding flange shows that the position of the butt welding nozzle is very strong and has strong sealing performance. It can be used for medium and high pressure, etc. On pipelines or equipment, such as chemical, petroleum, electric power and other high-pressure locations, such as high pressure, high temperature, flammable, explosive, toxic, harmful and highly toxic media can be used.

Installation Method

The WN butt welding flange itself is a whole. The butt welding method is used to connect to the pipeline. The butt welding nozzle of the flange is mainly used to weld the pipe or pipe fittings together. The welding method used is BW butt welding. After the welding is completed Weld inspection is required. Generally, the wall thickness of the end of the flange butt welding nozzle is consistent with that of the pipe.

GET IN TOUCH

Company:

Elite Piping Manufacture Co., Ltd.

Factory Address:

Office # 805, Building No. 6 Poly Metropolitan, Yongshum Town, Tongzhou District, Beijing, China.

Contact Person:

Michael

Contact Numbers:

+86 186 1829 1381

Email:

elite@elitepiping.com